From The Customer Viewpoint

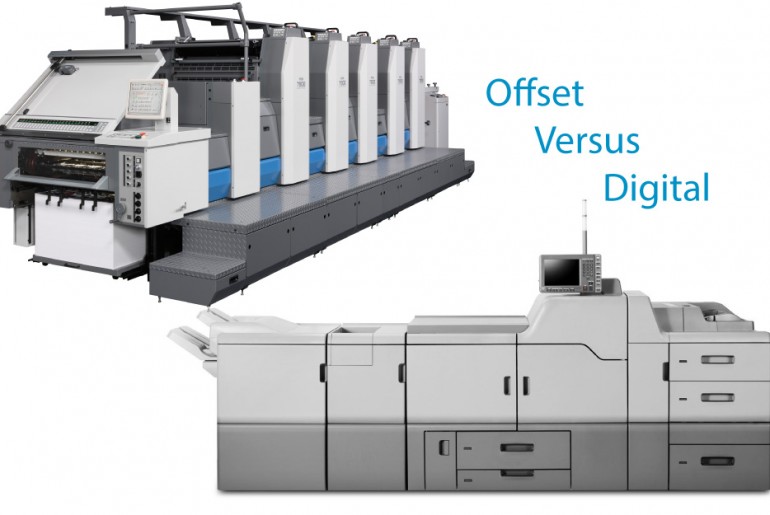

So which one is better, digital or offset printing? Well, most commercial printers in Kenya would not hesitate to give you their personal preference. The commercial digital printer would not hesitate to tell you that digital printing is better and the opposite would hold true for a commercial offset lithography printer. At Mint, we apply both as each has its advantages and disadvantages. In any situation, we advise the client as appropriate on which technology to apply. Often we get unreasonable demands from some clients insisting on a particular technology, turning down our advice for that particular technology.

Use the following checklist to determine which printing method you’d apply:

The first question is what are you printing? The nature of your publication will largely advise us on which method to apply. If it is a single template with one to three colours, then favour offset printing but not before asking the following question.

How many are you printing? If what you are printing is one to three colours and is in excess of about 500 copies, then you are better off printing with offset printing. The cost of printing one unit goes down with every increasing quantity (at times in batches).

The third question is how fast? Digital printing is quite simple compared to offset printing. The pre-press preparation of digital printing could take minutes compared to hours or days in that of an offset printer.

The question of colour again. Offset printing’s colour matching has for a long time been unmatched. This is before digital presses could offer advance colour management solutions ensure near perfect spot colours.

In summary we would advise a client to use digital printing in the following cases:

- When the data varies from page to page

- When the timelines involved are quite short

- When what you are printing is in smaller runs

- When proofing

And for offset printing:

- When you have long runs

- When the materials in need are not as urgent

From a Technical Viewpoint

Offset printing has been around for centuries now and its quality is largely dependent on the skills of the operator. Others are quite negligent and simple basics such as a clean blanket or rubber cylinder is not observed giving the printed product a faded look.

Offset printing’s benchmark is the reproduction of crisp clean text reproduction. Clean in the sense that when observed very closely, there are no small particles of ink surrounding the imaged area. The imaging quality is very good too, experts noting that it’s better than digital printers.

Digital printing has come of age and the number of substrates that can be printed on is ever increasing. Some speciality printers can print up to 600 GSM of stock paper. The quality of print is also increasing with its advantage being able to accommodate a wider gamut of colours. This is especially so in those that use inkjet technology.

The size of paper used in digital printers is commonly limited to 12×18 inches. Digital printer manufacturers are not asleep though and we’ve seen some presses being able to accommodate paper as wide as 14.33×22.5 inches. Some go further and print banner lengths of up to 1.2 meters increasing the scope of application.

This is however unmatched to that of offset printers being able to accommodate up to A1 sizes i.e. 23.386×33.11 inches.